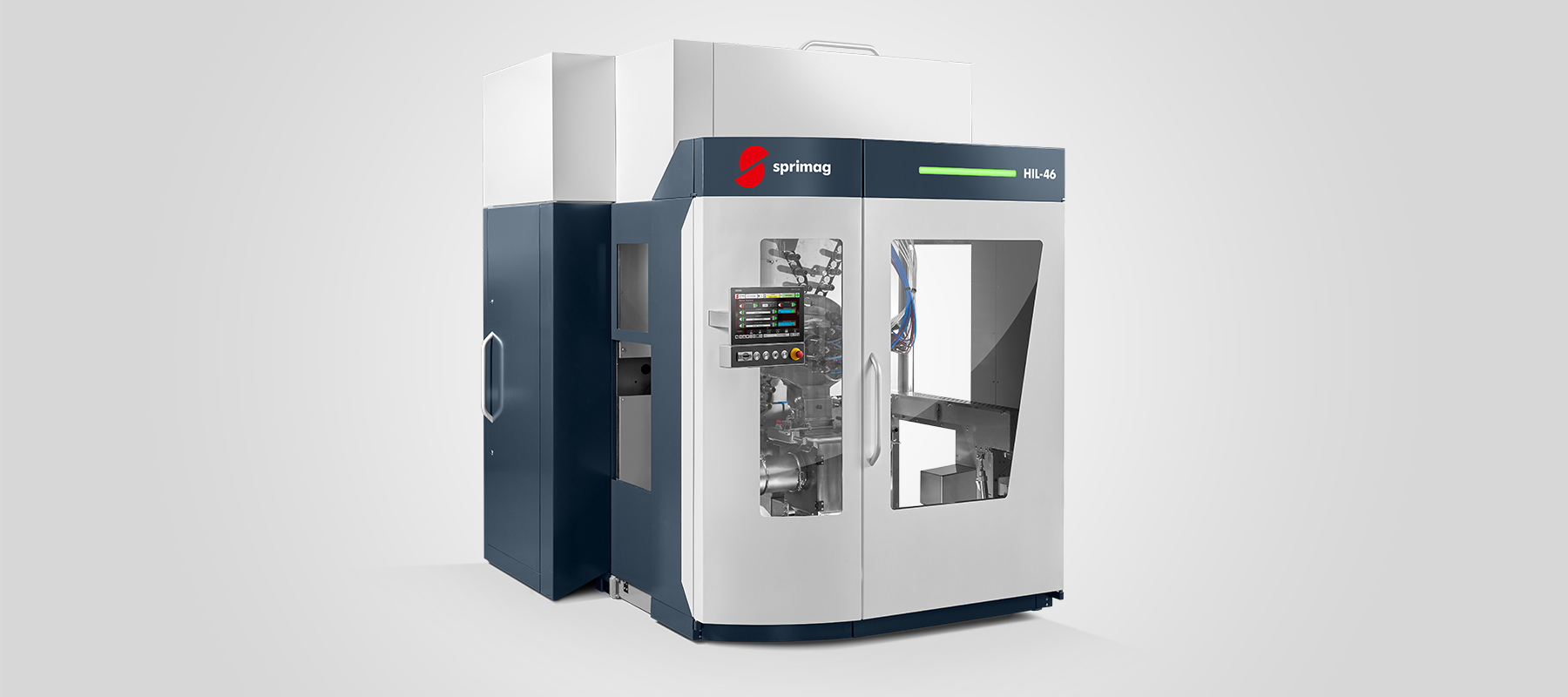

The HIL-46 NG internal coating machine for collapsible tubes impresses with its cost-, space- and energy-optimized coating concept. The internal coating machine, which is based on standard assemblies, is enhanced by energy-optimized system components, such as annealing furnaces and internal coating driers. Optionally, the machine can also be designed with an electrically heated evaporation zone as HIL-48 NG to achieve the best coating results through intermediate drying between the individual coating processes.

- Compact machine design

- Machinery speed up to 180 tubes per minute

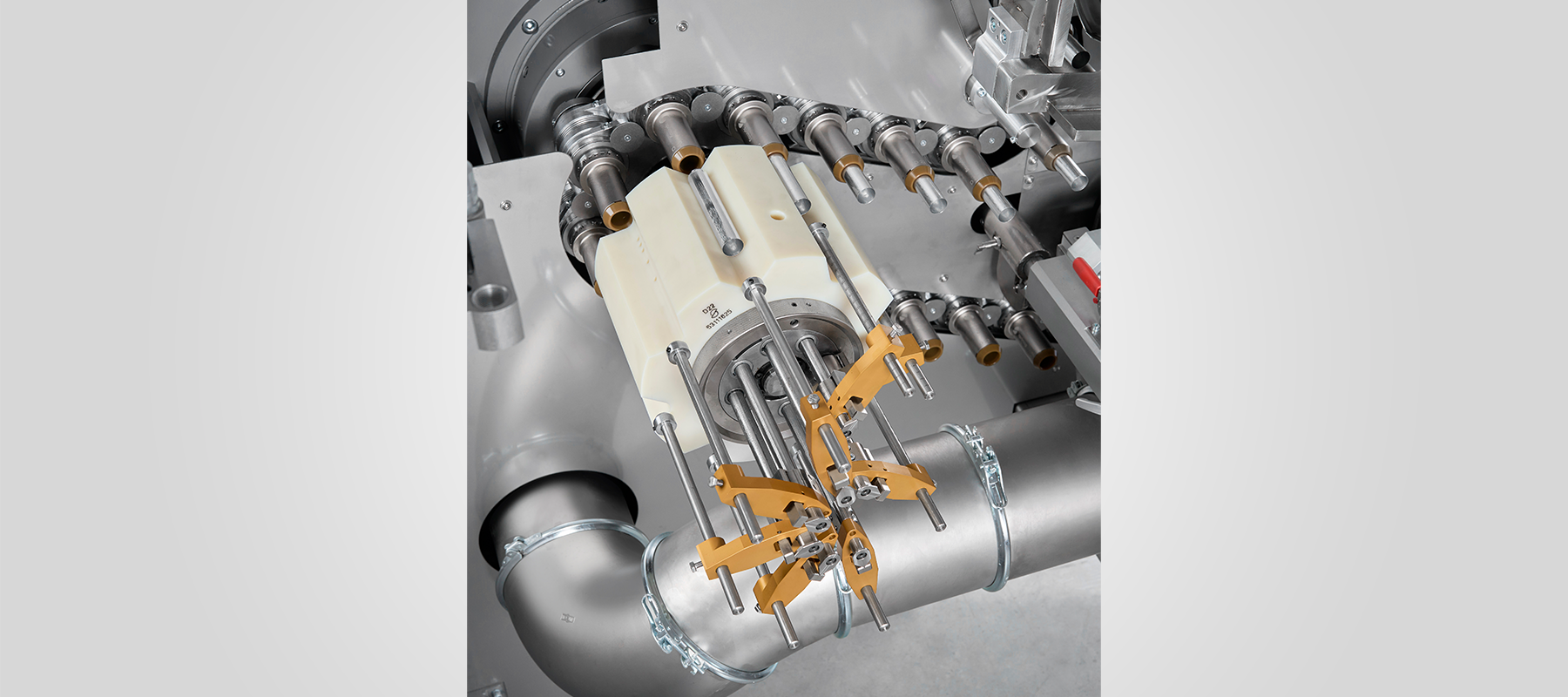

- Triple coating on 6 spray guns

- Increased operating convenience thanks to direct, electro-pneumatic control of the spray guns via HMI

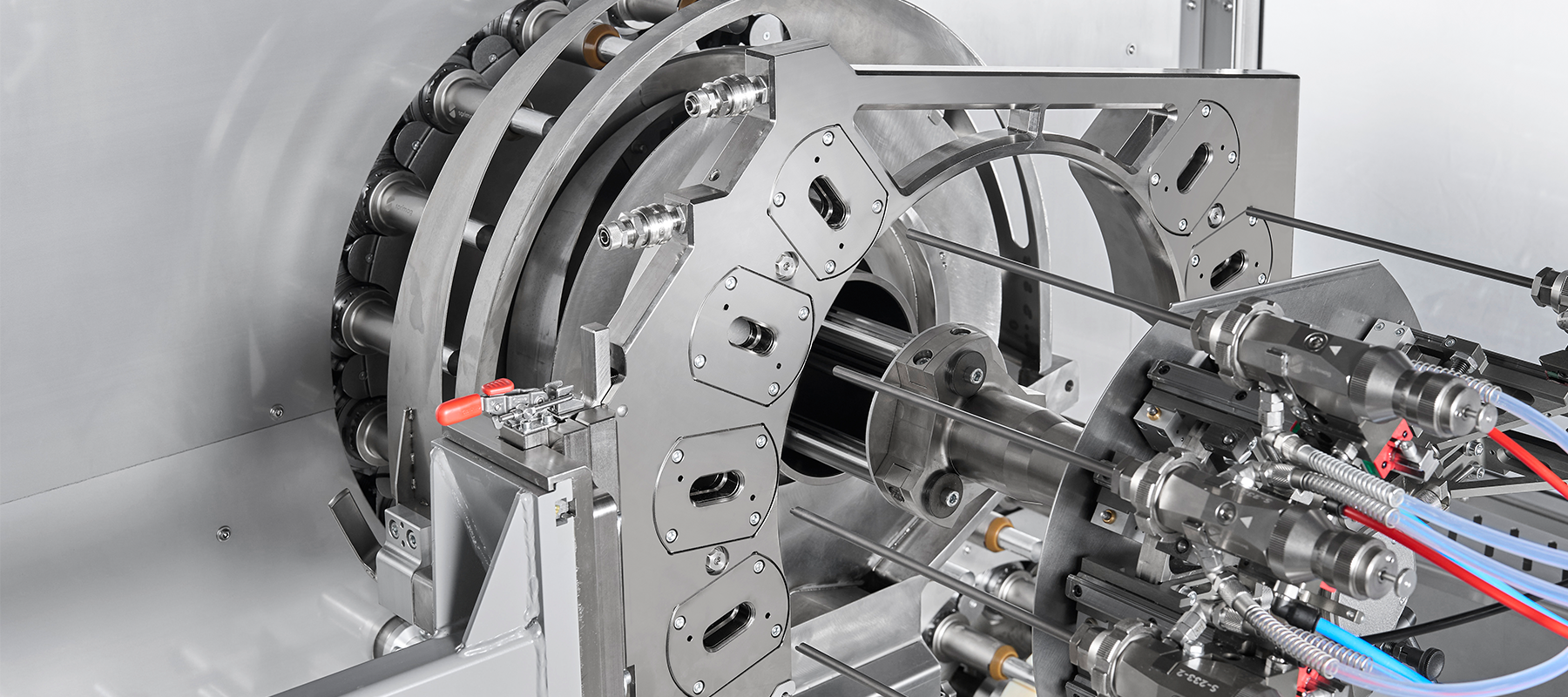

- Separate servo drives for stroke and transport movement

- Proven quick-change system for size parts

- swivelling HMI panel

- Automatic part ejection during production process

- Machine dimensions adjusted to integrate in older production lines

- Manufactured in accordance with the ATEX-regulations

OPTIONS

- Additional lacquer supply

- Cleaning device for spray gun extensions

- Energy optimizing system and vacuum control

- Second spray arm with full spraying equipment assembly

- Suction device for tubes without membrane

- RFID-access verification system

- Division of spray gun groups into separately controlled circuits

TECHNICAL DATA

- Product range: Aluminum tubes

- Product diameter: Dmin 10 mm, Dmax 50 mm

- Length: Lmin 70 mm, Lmax 220 mm

- Production speed: up to 180 tpm

- Spray guns/Spray process: 6/3 times

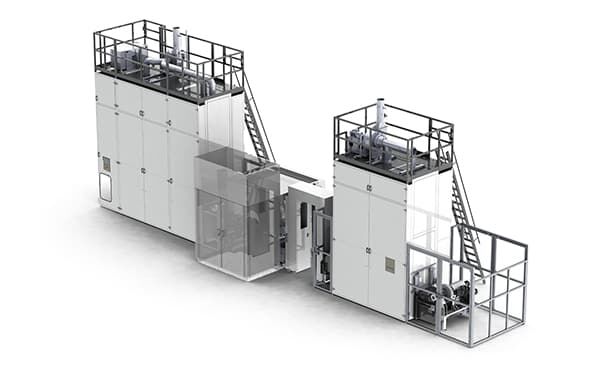

Annealing oven TGO + internal drier TIT

- Reduced wearout of the transport chain and the chain wheels by cardan-based drive system

- Chain tensioner with weight, electronically monitored

- Quadruple door lock

- Isolated doors with special door hinges for synchronized door closing

- Large outer doors with smooth surface on the oven‘s front and rear sides

- Quick and easy removal and reassembly of the shafts and chain wheels in case of service